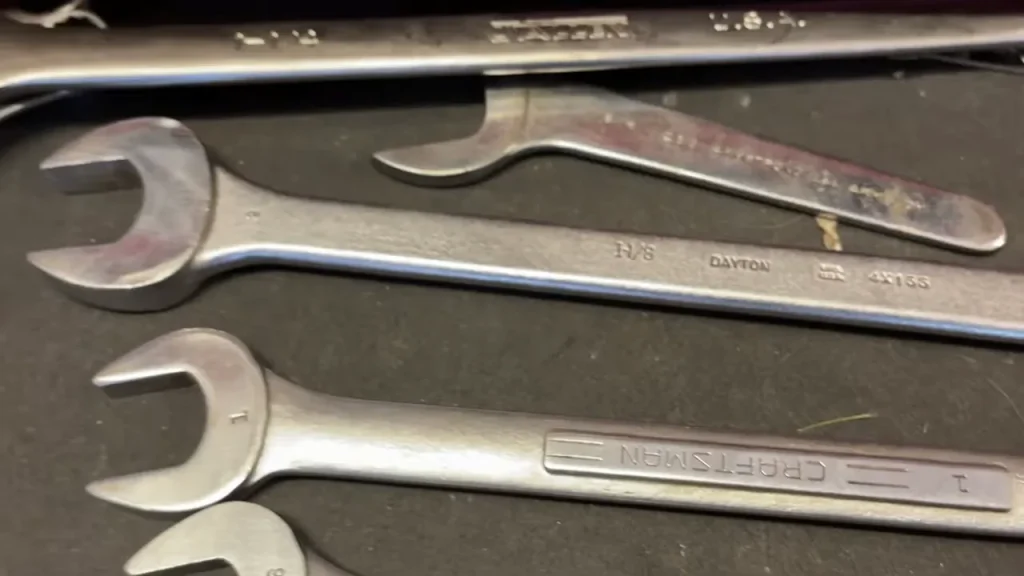

Metric Vs Standard Wrenches [What’s The Difference?]

Wrenches are indispensable tools in countless applications and industries, allowing us to tighten and loosen bolts, nuts, and fasteners with precision and ease. When it comes to wrenches, one fundamental distinction arises: metric vs standard.

The choice between these two systems depends on the measurement units used and the specific requirements of the task at hand. Understanding the differences between metric and standard wrenches is crucial for selecting the right tool for a given job.

In this article, we will delve into the topic of metric vs standard wrenches, exploring their importance in various applications and industries. We will shed light on the key differences between these two types of wrenches, examining their measurement systems, and discussing the implications of using the wrong wrench for a particular application.

Whether you’re a professional tradesperson, a do-it-yourself enthusiast, or simply someone curious about the intricacies of tools, this article will provide valuable insights into the world of metric and standard wrenches. So, let’s explore the differences, understand their significance, and discover how to choose the appropriate wrench for your specific needs.

What is Metric Wrenches?

Metric wrenches are essential tools in various industries and applications, particularly in regions where the metric measurement system is prevalent. These wrenches are designed to work with metric-sized fasteners, nuts, and bolts, providing precise and reliable torque for a wide range of tasks. To gain a deeper understanding of metric wrenches, let’s explore their features, sizing, and advantages.

1. Features of Metric Wrenches

– Metric wrenches are constructed with openings that correspond to metric measurements, typically in millimeters (mm).

– They are made from high-quality materials such as chrome-vanadium steel for durability and strength.

– Metric wrenches often feature a combination of open-end and box-end designs, providing versatility for different types of fasteners.

2. Sizing and Labeling of Metric Wrenches

– Metric wrench sizes are indicated by the width of the wrench opening or the diameter of the bolt it fits.

– The sizes are labeled using clear and standardized markings, making it easy to identify the right wrench for a specific metric fastener.

– Common metric wrench sizes range from small increments, such as 6mm or 8mm, to larger sizes like 24mm or 36mm, covering a broad spectrum of applications.

3. Common Applications and Industries

– Metric wrenches are widely used in countries and regions where the metric system is the standard measurement system.

– Industries that extensively utilize metric wrenches include automotive manufacturing, mechanical engineering, construction, and electronics.

– These wrenches are essential for assembling and maintaining metric-sized components, machinery, and equipment.

4. Advantages of Using Metric Wrenches:

– Compatibility: Metric wrenches ensure a proper fit with metric-sized fasteners, reducing the risk of stripping or damaging the bolts.

– Precision: The precise metric measurements allow for accurate torque application, preventing overtightening or undertightening of fasteners.

– Availability: Metric-sized fasteners, nuts, and bolts are readily available, making metric wrenches a practical choice for working with commonly used components.

– Global Standard: The metric system is widely adopted worldwide, facilitating international collaboration and standardization in industries that rely on metric measurements.

Exploring Standard Wrenches

Standard wrenches, also known as imperial or SAE (Society of Automotive Engineers) wrenches, are indispensable tools in industries and applications where the standard measurement system is prevalent. These wrenches are designed to work with fasteners, nuts, and bolts measured in inches rather than metric units. Let’s explore the features, sizing, and advantages of standard wrenches to gain a better understanding of their role and applications.

1. Features of Standard Wrenches:

– Standard wrenches feature openings that correspond to inch-based measurements, providing compatibility with fasteners measured in fractional or decimal inches.

– They are typically made from durable materials like chrome-plated steel or alloy steel, ensuring strength and longevity.

– Standard wrenches come in various designs, including combination wrenches with open-end and box-end configurations, as well as adjustable wrenches for versatility.

2. Sizing and Labeling of Standard Wrenches:

– Standard wrench sizes are labeled using fractional or decimal inch measurements, such as 1/4 inch, 3/8 inch, or 7/16 inch.

– The wrenches may also be labeled with the corresponding diameter of the bolt head or fastener they are designed to fit.

– Standard wrench sets commonly include sizes ranging from smaller increments, like 1/8 inch, to larger sizes like 1 1/4 inch, covering a wide range of applications.

3. Common Applications and Industries:

– Standard wrenches find extensive use in countries and industries where the standard measurement system is prevalent, including the United States and some parts of Canada.

– Industries such as construction, plumbing, electrical work, and machinery maintenance often require standard wrenches to handle imperial-sized fasteners.

– Standard wrenches are commonly used in industries that follow SAE standards, particularly in automotive repair and manufacturing.

4. Advantages of Using Standard Wrenches:

– Compatibility: Standard wrenches ensure a proper fit with inch-based fasteners, nuts, and bolts, preventing slippage or damage during use.

– Familiarity: In regions where the standard system is prevalent, using standard wrenches aligns with common industry practices and measurements.

– Versatility: Standard wrenches can be useful for working on older machinery, equipment, or vehicles that utilize imperial-sized fasteners.

– Specialized Applications: Some industries or specific tasks may require the use of standard wrenches due to historical conventions, equipment specifications, or regional preferences.

Comparing Metric and Standard Wrenches

When it comes to choosing between metric and standard wrenches, it’s important to understand the key differences and consider the specific requirements of your application. Let’s compare metric and standard wrenches in terms of sizing, compatibility, availability, and usage to help you make an informed decision.

1. Sizing

– Metric Wrenches: Metric wrenches are sized based on millimeters (mm) and offer a more precise range of measurements. They typically come in smaller increments, making them suitable for working with metric-sized fasteners and components.

– Standard Wrenches: Standard wrenches are sized based on inches and often use fractional or decimal measurements. They cover a broader range of sizes, including larger increments, which are commonly used with imperial-sized fasteners.

2. Compatibility

– Metric Wrenches: Metric wrenches are essential when working with metric-sized fasteners, nuts, and bolts. They provide a precise fit and help prevent slippage or damage to the fasteners.

– Standard Wrenches: Standard wrenches are designed for use with imperial-sized fasteners. They are compatible with older equipment, machinery, or vehicles that utilize inch-based measurements.

3. Availability

– Metric Wrenches: Metric-sized fasteners and components are widely used in many industries and regions worldwide, particularly in countries that have adopted the metric measurement system. As a result, metric wrenches are readily available and can be easily found in stores and online.

– Standard Wrenches: While standard wrenches are still widely used in specific industries and regions that follow the standard measurement system, they may be less commonly available compared to metric wrenches, especially in regions where the metric system is predominant.

4. Usage

– Metric Wrenches: Metric wrenches are commonly used in industries such as automotive manufacturing, mechanical engineering, and construction, where the metric measurement system is prevalent. They offer advantages in terms of accuracy, compatibility with metric-sized fasteners, and adherence to global standards.

– Standard Wrenches: Standard wrenches are often utilized in industries that follow the standard measurement system, such as certain sectors in the United States. They are suitable for working on equipment, machinery, or vehicles that utilize imperial-sized fasteners and where metric measurements may not be as common.

Choosing the Right Wrench for the Job

Choosing the right wrench for a particular job is essential to ensure proper fit, prevent damage to fasteners, and ensure efficient and accurate work. Here are some factors to consider when selecting the appropriate wrench for your specific task:

1. Fastener Size

Determine the size of the fastener you need to work with. If it is metric-sized, choose a metric wrench. If it is imperial-sized, opt for a standard wrench. Refer to the appropriate measurement system (metric or standard) to ensure a proper fit.

2. Wrench Type

Consider the type of wrench that suits your needs. Common types include combination wrenches (with open-end and box-end configurations), adjustable wrenches, socket wrenches, and ratcheting wrenches. Choose the type that provides the best access and grip for the specific task.

3. Workspace Constraints

Evaluate the space and accessibility of the work area. If you have limited space or need to work in tight corners, a stubby wrench or a wrench with a swivel head may be more suitable. These specialized wrenches allow for easier maneuverability in confined spaces.

4. Application and Torque Requirements

Consider the nature of the job and the torque requirements. For heavy-duty applications, such as automotive repairs or industrial tasks, select a wrench made from high-quality, durable materials capable of handling higher torque levels.

5. Comfort and Grip

Ensure that the wrench you choose provides a comfortable grip. Look for ergonomic handles, non-slip coatings, or cushioned grips that enhance comfort and reduce hand fatigue during prolonged use.

6. Quality and Reliability

Invest in a reputable brand or quality wrenches to ensure durability, accuracy, and longevity. High-quality wrenches are less likely to slip, round off fasteners, or wear out quickly, providing better overall performance and reliability.

7. Task-Specific Wrenches

Some tasks may require specialized wrenches, such as pipe wrenches for plumbing work or torque wrenches for precise torque application. Assess the specific requirements of your job and determine if any specialized wrenches are necessary.

Tips for Transitioning Between Metric and Standard Wrenches

Transitioning between metric and standard wrenches may be necessary in certain situations. Here are some tips to help you smoothly navigate the switch:

1. Familiarize Yourself with Both Systems

Take the time to understand the differences between metric and standard measurements. Learn the corresponding sizes and conversions between the two systems. This knowledge will help you select the appropriate wrenches for your tasks.

2. Identify the Measurement System

Determine whether the fasteners you’re working with are metric or standard. Check the markings on the fasteners or consult the equipment’s specifications to ensure you’re using the correct measurement system.

3. Use the Right Wrench

Select the wrench that matches the size and measurement system of the fastener. Using the wrong wrench size or measurement system can result in slippage, rounding off the fastener, or damage to the wrench.

4. Maintain Separate Tool Sets

If you frequently work with both metric and standard fasteners, consider keeping separate tool sets for each measurement system. This approach ensures you have the appropriate wrenches readily available, minimizing the need for constant switching.

5. Utilize Conversion Tables or Charts

Keep conversion tables or charts handy to help you quickly convert between metric and standard measurements. These references can be useful when encountering fasteners or specifications in a different measurement system than your default set of wrenches.

6. Pay Attention to Labels and Markings

Metric and standard wrenches are typically labeled or marked to indicate their respective measurements. Familiarize yourself with these markings to easily identify the correct wrench for the task at hand.

7. Practice and Adapt

Transitioning between metric and standard wrenches may require some practice to become comfortable with both systems. With time and experience, you’ll develop a better understanding of the different sizes and measurements, making the transition smoother.

8. Seek Guidance if Unsure

If you encounter unfamiliar measurements or are unsure about the appropriate wrench to use, don’t hesitate to seek guidance. Consult equipment manuals, online resources, or knowledgeable colleagues who can provide assistance and ensure you’re using the correct wrench for the job.

FAQ:

Q: What is the difference between metric and standard wrenches?

A: Metric and standard wrenches differ in terms of the measurement system they are designed to work with. Metric wrenches are used with metric-sized fasteners, which are measured in millimeters (mm). Standard wrenches, also known as SAE wrenches, are used with standard or imperial-sized fasteners, measured in inches.

Q: Can metric and standard wrenches be used interchangeably?

A: It is generally not recommended to use metric and standard wrenches interchangeably. Metric and standard wrenches have different sizes and are designed to fit specific fasteners measured in their respective systems. Attempting to use the wrong type of wrench may result in improper fit, slippage, rounding off of the fastener, or potential damage to the wrench or the fastener.

Q: In which industries or regions are metric wrenches commonly used?

A: Metric wrenches are commonly used in industries and regions that follow the metric measurement system. They are prevalent in industries such as automotive manufacturing, mechanical engineering, construction, and various other sectors worldwide. Countries that have adopted the metric system, including most of Europe, Australia, and many Asian countries, use metric wrenches as a standard tool.

Q: Where are standard wrenches primarily used?

A: Standard wrenches are primarily used in industries and regions that follow the standard or imperial measurement system. The United States is a prominent example of a country where standard wrenches are widely used. Certain industries, such as construction, plumbing, and electrical work, still rely on standard wrenches for working with imperial-sized fasteners.

Q: Are metric wrenches more precise than standard wrenches?

A: Metric wrenches are often considered more precise because they are based on the metric system, which provides finer gradations in sizes. Metric measurements in millimeters allow for a more accurate fit with metric-sized fasteners. However, it’s important to note that the level of precision required depends on the specific application and the tolerance of the fasteners being worked with.

Q: Can I convert between metric and standard measurements?

A: Yes, conversions between metric and standard measurements are possible. However, it’s important to note that the conversion is not always exact due to the difference in measurement systems. Conversion charts or online tools can be used as references for converting between metric and standard measurements, but it’s generally recommended to use the appropriate wrench for the specific measurement system to ensure the best fit and accuracy.

Q: Should I have both metric and standard wrenches in my toolbox?

A: If you work on a variety of projects or encounter both metric and standard fasteners, it’s beneficial to have a comprehensive toolbox that includes both metric and standard wrenches. Having both types of wrenches ensures you have the appropriate tools for different applications and allows for greater versatility in handling a wider range of fastener sizes and measurement systems.

- Why Are My Car Headlights Not Bright Enough? - May 9, 2024

- How Long Can You Drive With An EVAP Leak? - May 9, 2024

- What Does B Stand for in a Car? [Full Guide] - May 9, 2024

![How To Easily Reset Oil Light On The Jeep Renegade [A Quick Guide]](https://automhelp.com/wp-content/uploads/2023/07/Easily-Reset-Oil-Light-On-The-Jeep-768x461.png)